Ever wondered how your cycling jersey was made? Or your speed skating skin suit, gymnastics leotard, basketball uniform, team tracksuit or other custom sportswear? Even if you’re not familiar with the word, you will have seen sublimation printing everywhere. It’s also on t-shirts, leggings, socks as well as other items like banners, ID cards and metal signs.

But not all sublimation is created equal. Great care and skill is required to achieve perfection in colour matching, sharpness and vibrancy to give a high quality final garment.

At EA HQ in Melbourne, we live and breathe sublimation daily. After over 14 years in the trade, we pride ourselves on the quality and technicality of the custom sportswear we produce. But just HOW is it done?

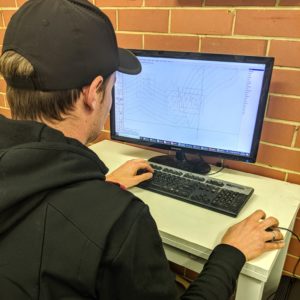

1. Artwork design

The process begins at the computer. Artwork concepts are created based on client specifications, including garment type, team colours and logo, sponsor logos, custom names and numbers, and design brief. We must also consider seam placements and how this will affect the design flowing smoothly across the entire garment. It can take 30 minutes to many hours to design sample concepts and refine them with the client to get to the final design for the custom sportswear.

2. Artwork placement onto panels

Once the final artwork is finished, it’s placed onto each garment size, panel by panel. To get a perfect result, we have to carefully consider correct scaling, seams and trims. The next step is to replicate the panels to give the total number of garments required per size.

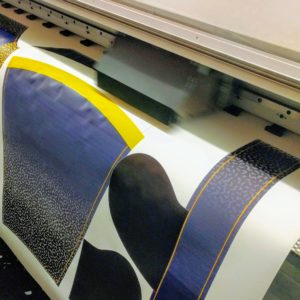

3. Printing

The final artwork is printed on large-format ink-jet printers which are around 1.8m wide and weigh around 500kg. The printers are specialised for sublimation and require specific sublimation inks, and the paper is also specialised for sublimation. There is a lot of technical expertise and mechanical parts required to keep these delicate printers operating smoothly. Just one small defect in one of the multiple print heads will show up in the finished garment. Quality of printing is a common difference between high and low standard custom sportswear.

4. Cutting fabric panels

Did you know that all sublimation fabric starts off white? We procure world-class, cutting-edge sports fabrics from Europe, including the newest aerodynamic fabrics which are used by top-level competitors in competitions such as Tour de France. We carefully hand-select one or multiple fabrics for each garment type. The white fabric is cut into the panels required for the garments, grouped by garment size. Fabric for sublimation must be at least 75% polyester in order to absorb sufficient ink during the heat pressing process.

5. Heat pressing

This stage is when the colours pop and the garment comes to life! The printed roll of paper is set up on the heat press machine, and the blank panels are placed one by one onto the corresponding printed artwork. It is then run through the heat press at 205oc. This process heats the ink in the paper until it transforms into a gas. Being pressed firmly against the fabric, the ink gas is then absorbed into the polyester fibres of the fabric. This permanently dyes the fabric, resulting in vibrant, colourfast and durable custom sportswear.

6. Sewing

Once the fabric panels have been printed, they are sewn together to form the final garment. We use a range of stitches including flat lock, cover stitch, straight stitch and more. It takes a great amount of skill and experience to sew complicated garments such as cycling gear, ice speed skating suits and inline speed skating suits.

7. QC

The final step is quality control. Garments are given a final check to ensure that loose threads have been trimmed, the artwork is perfect and the garments are assembled to specifications.

8. Delivery!

The final garments are finished and sent out to our eagerly awaiting clients! We love receiving feedback and photos from clubs, schools and teams enjoying the gear we make. It truly is an art form and labour of love that we proudly undertake here in Australia.

We love working with clubs to design Australian Made custom sublimated sportswear. We specialise in technical sportswear for racing and performance sports such as gymnastics and artistic skating. Enquire with us today!

Special thanks to our partners Skate Australia.